COMPOUNDING PLANT

Startseite » Services » Compounding Plant

Own compound production for black and coloured elastomer compounds

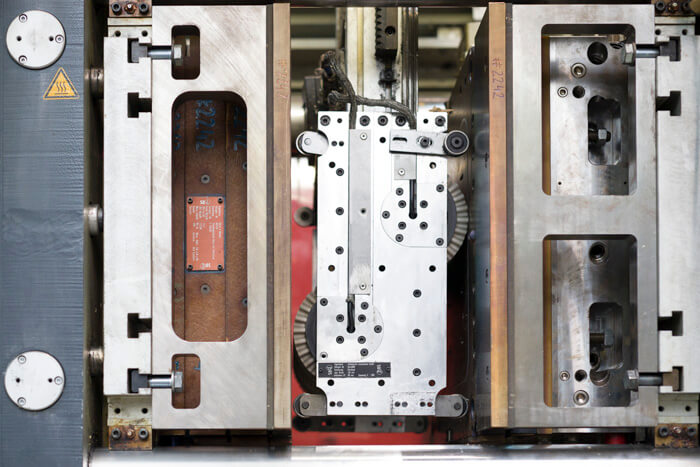

Our own mixing plant with several mixing rollers enables us to be independent, flexible and fast in the production of rubber compounds for our vulcanisation. The best possible dispersion and homogeneity of the rubber mixture is achieved by production on rolling mills. This is the only way to achieve the best surface qualities. The quality of the elastomer compound is the basis for economical vulcanization of elastomer parts according to customer specifications.

The experience gained in elastomer compounding is also decisive in ensuring the quality of the finished compounds purchased from our partners.

SBG continues to focus on own compound production

On the market for the production of mixtures, it is becoming increasingly apparent that small and very small quantities can only be obtained with an increased price surcharge. The most common sizes for a batch of compounds are between 125 and 350 kg for the established compound manufacturers. These quantities are not economically viable for the production of micro parts or small series. Therefore, it is and remains essential for SBG to have its own compounding capabilities.

With our existing equipment, mixing batches from 1 to 40 kg can be produced. SBG thus ensures flexibility and cost-effectiveness for small series and micro-vulcanization projects.