TOOL DESIGN

Startseite » Services » Tool design

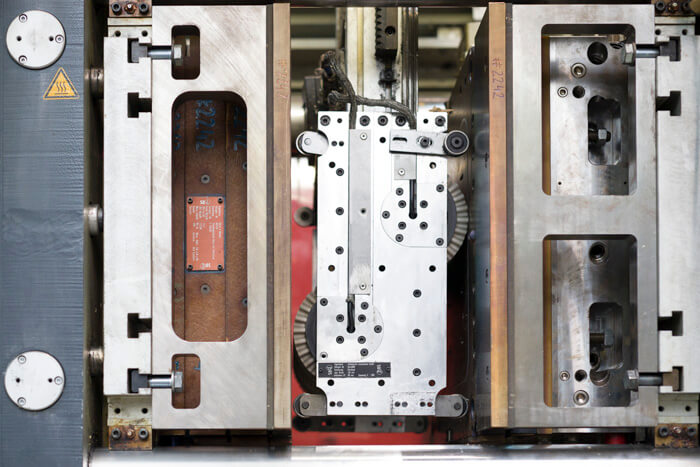

CONSTRUCTION IS THE BEGINNING AND DECISIVE FOR SUCCESS

The basis for a cost-efficient production is in the tool design. In order to meet the requirements of modern elastomers, we contribute all our experience and expertise. We manufacture your tool with the required specifications on time and cost-effectively in Germany. No matter whether you are in the automotive, household appliance, control and regulation technology or in the occupational safety sector, the quality of our vulcanising moulds will convince you.

We have modern machinery at our disposal, which we constantly adapt to the state of the art. This enables us to exploit the cost advantages of current production methods. Our own design department provides you with the support you need during the development phase of your product and ensures an optimized tooling and product design.

In this way, decisions can be made at an early stage that save costs in the long term. Our competence in toolmaking lies above all in our experience and in our network of competent partners as an extended workbench. Our spectrum ranges from CM tools for highest surface quality or large-volume rubber moulded parts / rubber-metal composite articles to transfer moulding tools for medium-sized series to precise IM vulcanising tools for fully automatic production (horizontal or vertical).

In addition, cold runners or tempered ITM pots are taken into account in the manufacturing concepts, depending on the material and process. Finally, we are in a position to optimally match the tools to the production due to the proximity to our production.

Take advantage of our design knowledge of vulcanizing tools for the manufacturing of precise rubber mouldings, rubber-plastic composites and rubber-metal composite products!